5 Simple Statements About DTF Transfer Explained

5 Simple Statements About DTF Transfer Explained

Blog Article

continue to keep the silica gel pack saved using your unused UltraColor Max transfers to maintain humidity faraway from transfers

push: The well prepared movie is put on to the fabric Using the printed facet down. utilizing a heat press, the movie is pressed on to the substrate of preference for the encouraged software configurations.

right after printing, a powdered adhesive is placed on the print whilst it’s even now wet. The film is then cured within an oven or warmth push, solidifying the adhesive.

5″ in width and peak, centered somewhere around one″ higher than the top fringe of the sleeve seam. Pro tip: decide on the right sleeve for balancing out a left upper body print, or decide on either sleeve for your standalone impression.

immediate-to-film warmth transfers also give more overall flexibility when it comes to the kinds of garments you are able to print on. classic display screen printing frequently calls for specialized inks or products for printing on specific sorts of fabrics, for example nylon or spandex.

An ideal DTF warmth press, crucial for correct application, allows people good-tune unique options determined by the garment and transfer variety.

Understanding your printers well will help you accomplish much better brings about DTF transfers. hence, it is important to possess awareness concerning the options of the DTF printers.

Vibrant and read more Durable Prints: DTF transfers develop lively hues with excellent sturdiness. The prints are immune to washing and wear, making sure they retain quality eventually.

With Direct-to-movie heat transfers, you may print many patterns in just one purchase, without having to meet a bare minimum get amount. This lets you supply more range on your shoppers and examination out various designs to discover what sells very best.

When figuring out the size of the heat transfer, criteria should be produced with the print space – the surface area of The material which the ink or structure will protect. becoming aware of pockets, seams, buttons, along with other garment features is significant to circumvent any style and design distortion or unintended overlaps.

Yellowing of adhesive or waffle texture to the carrier is possible and regular; this will not impact application.

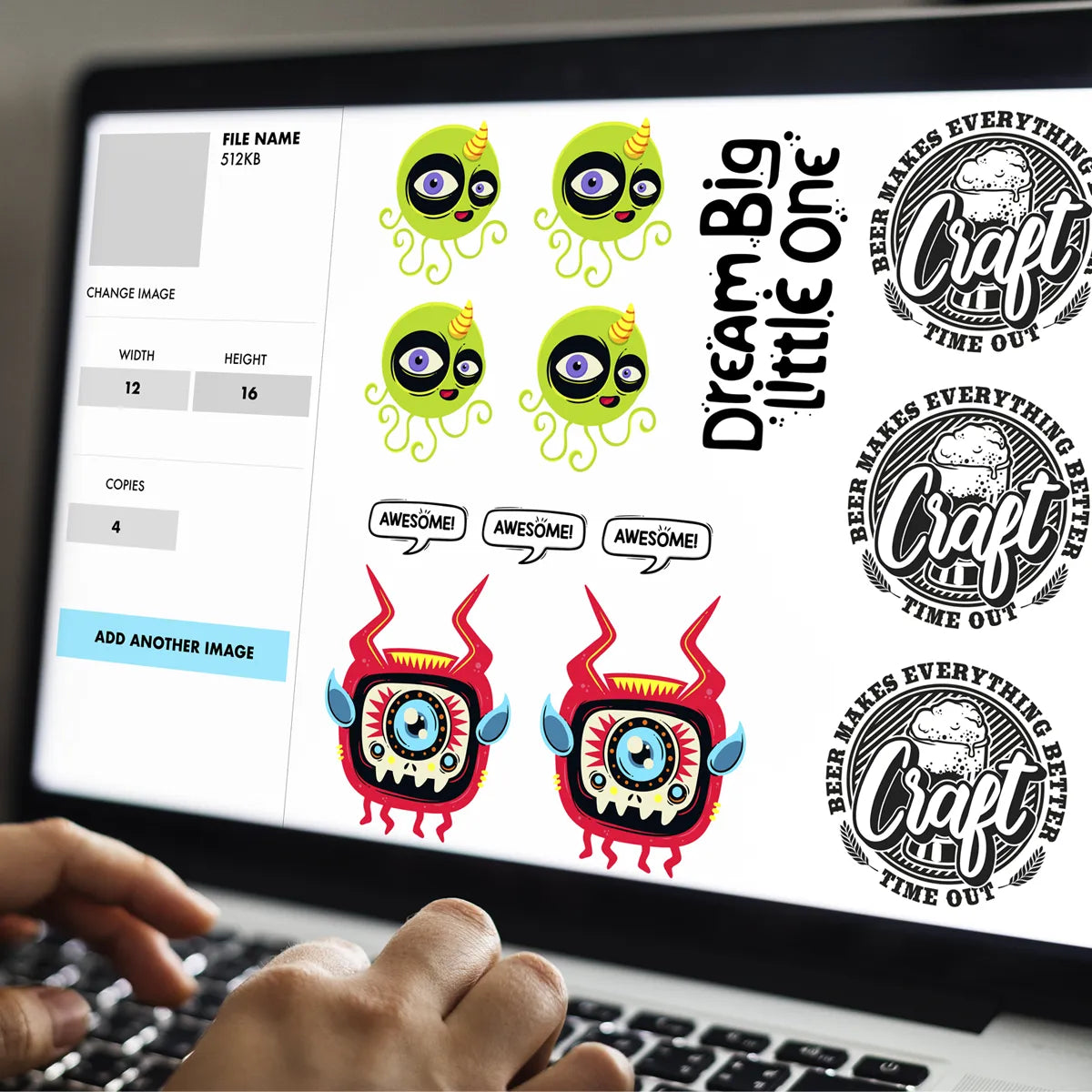

Upload: future, you might add your structure; opt for the appropriate transfer sheet sizing together with printed style and design dimension in inches (if a particular design measurement is required); indicate the volume of transfers essential; and specify your garment form/coloration. if you want a precise reorder, be sure to allow us to are aware that at the same time.

gurus looking for much more insights can make reference to “DTF which means in printing your apparent guide” and utilize the "DTF transfer placement guide" and "best DTF heat press settings guideline" for most effective outcomes.

With DTF printers, you can easily obtain the specified print mainly because they are recognized for their superior print quality, and the applying approach can also be really simple.

Report this page